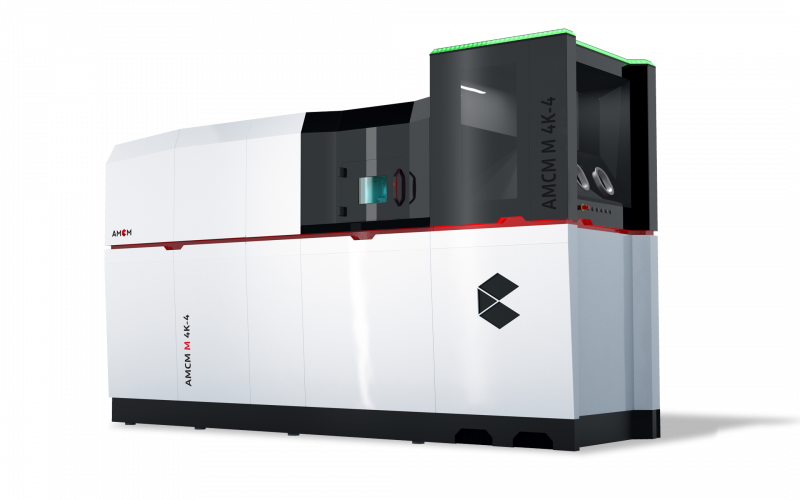

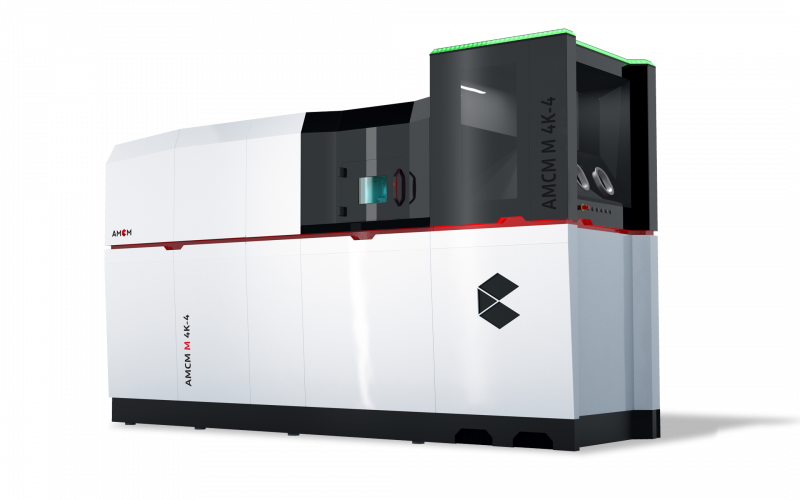

AMCM M 4K

Large scale, high productivity system for demanding AM applications. 1 meter building height with up to 4 x 1,000 W laser power.

Think big.

.png)

The U.S. launch company Launcher is building complete combustion chambers and injectors for liquid rocket engines with a thrust of 10 tons on a custom AM large-scale system from AMCM and testing them at NASA Stennis Space Center.

AMCM M 4K 3D-printed combustion chamber of Launcher's E-2 engine is printed in one piece and will be used in the first stage of its orbital launch vehicle to put small satellites into orbit.

Back in 2018, Max Haot, CEO of the rocket company Launcher was looking for a solution to print entire combustion chambers for their Launcher E-2 engine. Those parts are typically 450 x 450 x 1000 mm in dimensions, are made of CuCrZr and have intricate internal regenerative cooling channels.

Such a solution did not exist at that point in time. There was no dedicated AM process for CuCrZr, and no AM system would be able to produce such dimensions as a single part, which is critical to achieve high performance and low cost.

AMCM has carefully listened and has analyzed our requirements to come up in record time with a large scale system capable of successfully printing our combustion chambers

Together with Launcher, AMCM defined the requirements to the AM system and started the development of a dedicated AM Machine based on the reliable M400 platform from EOS. Only 9 month later, AMCM released the first AMCM M 4K with 450 x 450 x 1000 mm (x, y, z) build volume, and printed a first combustion chamber model out of AlSi10Mg.

Large scale, high productivity system for demanding AM applications. 1 meter building height with up to 4 x 1,000 W laser power.

Think big.

In parallel, AMCM partnered with the material & process development department of EOS in Finland to develop and test processes for CuCrZr. Resulting from this cooperation, first real full size CuCrZr combustion chambers have successfully been printed on the AMCM M 4K.

Launcher won a prestigious award from the U.S. Air Force with this part. Along with a substantial financial contribution, Launcher was also granted access to NASA’s Stennis Space Center facilities to build their test stand and test the AMCM M4K printed parts. Getting access to such a costly and scarce resource is a substantial commitment and sign of trust, that was well deserved by the Launcher team after all their achievements.

Images courtesy of (also the cover image) Launcher/John Kraus

We are at formnext in Frankfurt 18. – 22.11.2024 - Visit us at our booth D49, hall 11.1